| Navigation |

| Geo-Dome Home |

| Forum Home |

| View All Threads |

| New thread |

| Member login |

| Title: | Hub design | |

| Posted on: | 3/24/2011 9:56:39 PM | |

| Category | General dome conversation | |

| Author | Dave | |

| Status | Open | |

| Views | 7239 | |

| Replies | (7) | |

Hi everyone

I''d first of all like to introduce myself.

My name is Dave and I was a builder for most of my working life. I recently moved into a house with a big enough garden to be able to build my first dome.

I have been reading this site now for a few weeks and I must say it has been very informative. After all the reading I''ve done on domes, it seems to me that the biggest problem is not the struts or the cover, it''s the hubs. I searched the internet and they are impossible to find except in kits.

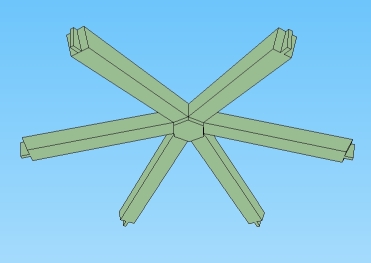

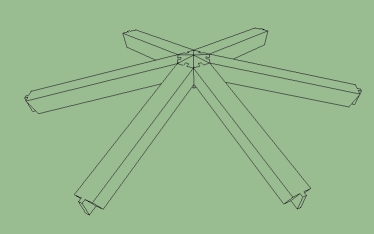

For a permanent dome (greenhouse)I plan to use a hardwood hub morticed and tenoned and glued and pinned as in the pictures.

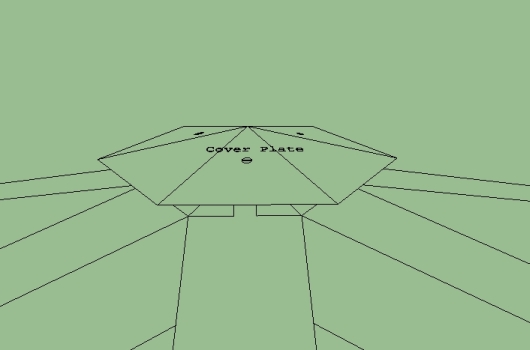

For a dome that can be dismantled (garden shed)I plan to use dovetail joints and a covering/restraining plate to keep the joints in place without glue or pins.

For a permanent dome (greenhouse)I plan to use a hardwood hub morticed and tenoned and glued and pinned as in the pictures.

For a dome that can be dismantled (garden shed)I plan to use dovetail joints and a covering/restraining plate to keep the joints in place without glue or pins.

As the maths and angles have all been gratefully made available on this site I just need to allow for the tenons and fashion the plates out of a maleable metal, zinc or copper should do.

I would be grateful for any input as this is my first dome.

Hope I''ve done this right:)

As the maths and angles have all been gratefully made available on this site I just need to allow for the tenons and fashion the plates out of a maleable metal, zinc or copper should do.

I would be grateful for any input as this is my first dome.

Hope I''ve done this right:)

|

|

|

|

| [ Comments 7 ] |

| posted by admin | 24/03/2011 23:40:21 |

| Hi Dave, welcome to the site, I'm really glad you have found the information useful. OK your design looks feasible but I'm not sure how you intend covering your dome. Have you seen the : video on the plans page I use this method to build domes that can be covered with any material (plastic, glass, perspex etc) and there are no hubs. There are no tenons either so you could save yourself a lot of work. Take a look and let me know what you think. | |

|

|

| posted by Dave | 25/03/2011 00:23:08 |

| Hi Admin I watched your video and must agree that it is a much simpler method of constructing frames. Would I be correct in saying that the long side of each strut has to be run up on the table saw so that when they come together the angles form the frame? The reason I thought of the hub/mortice and tenon method was for the strength these joints provide. I was thinking of using a uv covering for longer life on the greenhouse and cladding on the shed. I need these structures to be permanent (at least five to ten years) | |

|

|

| posted by jamie clarke | 25/03/2011 21:37:52 |

| i was also wondering about what angle the band saw is used to cut at and thought it would be good if this could be incorporated into the calculator. | |

|

|

| posted by Admin | 29/03/2011 23:38:49 |

| Mortise and tenon will be really strong under compression but not so good under tension, unless you have some sort of peg to hold the tenon in place. The other thing is the metal cap on the hubs, will you put the cover over them or under them? | |

|

|

| posted by Dave | 30/03/2011 00:43:41 |

| Hi Admin In answer to your question, I was thinking of making the hubs longer on the underneath allowing the tenon to sit on a about 1" of solid wood preventing any downward movement and the cap above with a screw into each strut preventing any outward movement. I will be making the first frame in about a week and will load it with weights until it reaches its breaking point. Will upload pics when destruction is complete:) On a 2v 1.5 radius dome, what would you guess the breaking point to be with this type of hub and we'll see how close you get. | |

|

|

| posted by Admin | 30/03/2011 22:48:21 |

| It depends on a very wide set of variables, Timber size, load centre of gravity, how it's fixed down, Quality of joints, glue type etc. If you are just making one section (say a pentagon section) you will have to firmly fix it to a sheet of ply or it will just split open. If you do a half sphere and fix it down firmly my guess would be that you'll run out of concrete blocks before it breaks. | |

|

|

| posted by Michael | 07/07/2011 17:27:17 |

| My name is Michael and I have just finished cutting all the struts for a 9' radius 3v dome. I am going to try hollow hubs . Each face of the polygram will be an individual panel cut to the appropriate angle. Does anyone have the correct pattern or angles for the four way hubs. Icoyld calc it out but I thought somebody has already been through this so I thought I would ask. The fourways at the bottom are obviously two faces on a 180 degree plane but the two struts coming in from the top will be at the angle of the intersecting struts. My construction material of choice is 1 x 3 pine. | |

|

|

Login to add resources

Copyright © 2013 Geo-Dome.co.uk. All Rights Reserved.