| Navigation |

| Geo-Dome Home |

| Forum Home |

| View All Threads |

| New thread |

| Member login |

| Title: | 2v dome for a dummy | |

| Posted on: | 4/23/2009 1:49:17 AM | |

| Category | Construction Techniques and Tips | |

| Author | domie | |

| Status | Open | |

| Views | 12559 | |

| Replies | (11) | |

| Hi, I am trying to build a 5'' diameter 2v dome for a playhouse for my daughter. I bought 1"x 1 3/8" wood for the struts and I am having trouble conceptualizing the EASIEST way to put this together. I have domebook 1 and 2 and have read the threads, but I''m having a little difficulty following exactly what needs to be done. I have been collecting tongue & groove siding from old homes in San Francisco and was planning to cut them to size and use them for the skin of each panel. At first I thought I would build the panels seperately, but now I am reconsidering that. It seems like I would use twice the wood for the frame and still have a lot of big spaces where they connect. I am also unsure exactly what angles to use. I have a standard radial arm saw, nothing fancy. I read about the 18 mm hub plate, which sounds like it might be a good fit, but I don''t really understand it exactly. I really need someone to lay out exactly what I need to do to get this frame up. The windows, doors and skin, I can handle. What is the absolute easiest way to construct the wood frame (keep in mind it is only 5''diameter, and will be covered). Here are some questions that might be good to know. 1. what is easier with wood struts, hub and strut or premade panels? 2. If I go with the preconstructed panels, what angle do I use for the end of each strut and what angle to I bevel the panels so that they join together nicely without spaces (when giving these angles, is this the angle I should dial in on my saw?) 3. If I do the premade panels, how many struts do I need of each size? 4. If I do the strut and hub method, do I still need to bevel anything? What would the end angles be for each strut? Would I do a double angle (similar to a stake?). Should I use a hub or a hub plate? what kind of hub would be easy to find and work with for this size project if I chose to go that route? 5. How does the hubplate work? I am visualizing the external hubplates you see on monkey bars at playgrounds. How do you make one from wood? Does it contour as you connect the struts? I guess I don''t really understand, since the wood hub plate would be flat. Thanks for your help. I plan to build several domes and this is my first attempt. I already have the wood and just waiting for a response, so I can get building. This site rocks, by the way! | |

|

|

| [ Comments 11 ] |

| posted by domie | 24/04/2009 00:03:06 |

| Just wanted to simplify my questions, to make it easier to respond. Can anyone provide me with a step by step of what I need to do to build a 5' diameter dome using 1" x 1 3/8" struts? thanks! | |

|

|

| posted by Paul E | 26/04/2009 16:39:27 |

| Your first question is overwhelming, the second too general, and considering that it's for your daughter,I'd hate to recommend anything where your skill level would cause anything to be built wrong and have her get hurt. If you want to build a few models (it's only 5 feet in diameter) try a pvc hub, then a plyhub, then a panel dome. I've only done a 13 foot diameter pvc hub, but am planning on a panel dome. The front page of this site shows a kit, that was based on an early article. I'll be reading up on that so that I understand it. One of the Domebooks also showed a plyhub with hardwood doweling and covered in redwood siding. Very nice. | |

|

|

| posted by BigJust | 28/05/2009 10:13:25 |

Hi all.

I have just finished making my first dome. It is only a 1m dia. but ideal as a cold frame. Anyway here are some pictures.

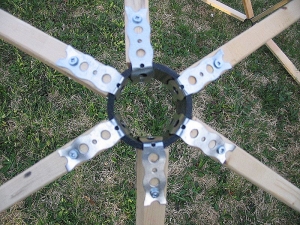

I used the hub and strut method and to fix it together I made some simple metal plates on the under side. I plan to try the same method but using pocket holes/screws on the outside of the frame, so I'll keep you posted.

I used the hub and strut method and to fix it together I made some simple metal plates on the under side. I plan to try the same method but using pocket holes/screws on the outside of the frame, so I'll keep you posted.

|

|

|

|

| posted by domealone | 16/06/2009 12:37:49 |

| Hi All. BigJust I'm very impressed with your cold frame dome. Very nice! It looks to be a really good size for a starter dome. As I'm being drawn into this whole 'dome' thing (which is strangely addictive), I'm hoping to start off making one similar to yours. Could you give me advice on the make up of the hubs please?. I take it they are tapered pentagons/hexagons and I guess I'd need to make up a jig to allow them to be machined using a thicknesser. Any advice gratefully received. Many thanks :) | |

|

|

| posted by Neodim Kollobok | 07/07/2009 01:28:35 |

A simple 6 ft diameter greenhouse, with hubs made from 3inch PVC pipes, covered with non-glare plexiglass

|

|

|

|

| posted by karlsdome | 07/07/2009 12:58:54 |

| Hi all, I'm looking at making a dome but can't decide on how to do the hubs. What would anyone recommend for a dome with a diameter of nearly 30foot. I will be using a mixture of plyboard for the bottom row with the rest being clear double layer acrylic. Metal plates were my first choice, but I am unsure if I have to prebend the metal to angles that suit the dome or would they naturally contour with the dome. The other method that I quite like is the plastic pipe hub, but I'm not sure how big the dome can be before the plastic hubs give out. I will be using wood for the frame, 1 inch thick and 3-4 inch wide. Thank you | |

|

|

| posted by Paul E | 09/08/2009 17:40:03 |

| My 13 foot diameter dome used lag screws screwed into the end grain like Neodim Kollobok shows. While that works great for a model, it is a very weak structure. I have seen pictures of 3 domes built with this method that collapsed shortly after they were covered. Granted they were not anchored down and encountered heavy winds, so whether they rolled and then collapsed, or the increased tension ripped the hubs out of the struts, I would not do it this way for anything that is covered, in my opinion. | |

|

|

| posted by Paul E | 09/08/2009 18:05:23 |

Go to flickr and search for "Dome Catastrophe 4" by Brown-Eyed Activist. Apparently I can't post links as per the rules, and can't download the larger pics from Flickr, so here is a small one.

|

|

|

|

| posted by chris | 18/06/2010 07:08:03 |

| Check out '12 degrees of freedom'. A Fuller Explanation By Amy C. Edmondson google "12 degrees of freedom" fuller explanation See Fig. 7-9 on p.108. I've built a bicycle wheel with only 12 spokes. When the slack is taken up by the 12th spoke to be tensioned, the hub immediately (and noticably) becomes rigidly fixed near the center of the rim. 'near' since the spoke lengths may vary from true (but can be tensioned equally, if the rim is solid enough). | |

|

|

| posted by chris | 18/06/2010 07:21:10 |

| Invest in the smallest two sizes of (bicycle wheel) spoke (nipple) wrenches. 'spoke wrench' is the usual term. Find a discarded child's bicycle wheel, with some defect nobody else will salvage. FRONT WHEELS ONLY. Rears are invariably messy. Remove the tire and tube, having marked it in some fashion to reorient it correctly on the rim, at some later date. Label every spoke with masking tape, starting at the air inlet valve. Mark one spoke found nearest to the valve hole, and its corresponding rim and hub holes as the 'Key' spoke. Now loosen all nipples, 1/2 turn each. Do it again until the hub feels a bit loose in the rim (don't unwind just one spoke; untension each of them a bit and repeat). Make sure you keep the spokes threaded into the nipples 2 to 4 turns at all times; if one comes away, try to rethread it back into the nipple immediately. Ponder the thing at length, and begin removing spokes. You can skip every n spokes, keeping things nearly symmetrical. Go online and look for Sheldon Brown's wheelbuilding article. Study it (and your wheel) carefully. Get to the point where you can have the entire wheel dismantled, spokes from hub, and reassemble it correctly, to finger (low) tension. Do this several times. It is highly instructive on how the 12 degrees of freedom get restricted in rigid structures. | |

|

|

| posted by Neodim Kollobok | 09/01/2011 20:28:56 |

| I have built 15feet dome according to a model that was shown in my previous post where I used 4inch ABS pipe as hubs for 2x4 struts. It is covered with plywood and slate and is successfully surviving second winter. I'll upload fotos of construction process, it took me about 2weeks to put up frame and cover it, working mostly alone. | |

|

|

Login to add resources

Copyright © 2013 Geo-Dome.co.uk. All Rights Reserved.