| Navigation |

| Geo-Dome Home |

| Forum Home |

| View All Threads |

| New thread |

| Member login |

| Title: | Festival camping dome help needed | |

| Posted on: | 5/16/2008 8:27:28 PM | |

| Category | Questions and answers | |

| Author | out2lunch | |

| Status | Open | |

| Views | 4413 | |

| Replies | (5) | |

I''ve seen a few domes at various festivals over the last few years. I thought this could be a nice festival environment for friends and I to relax in.

I''ve been reading and searching through the web, and most sites seem to talk about metal struts. I would prefer to use wooden struts (perhaps broom handles)fixed into hubs made out of a cross section of say plastic drain pipe. (I''m not the most DIY friendly person, but always up for a challenge).

I thought of trying a simple 2V design, with say 4ft broom handles for the A strut. According to desert domes reverse dome maker calculator this would give the following -

A radius/height of 6.47ft

Which sounds ample for a comfortable festival sleeping and chilling space.

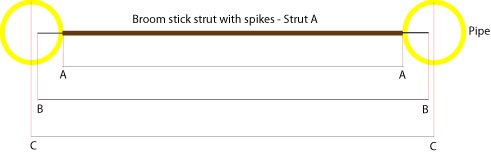

Now the question I have it If I put a spike at each end of the broom handle that slots into the hub, to I have to add 50% of the hub each strut for the calculations for the B strut, or 100% of the hub size? Or by some magical mathematical madness, you don''t need to worry about the strut length in this way.

I''m sorry if this sounds confusing, I''m a bit confused myself, I''ve drawn a quick diagram to try to explain what I''m on about...

|

|

|

|

| [ Comments 5 ] |

| posted by colin | 17/05/2008 16:01:29 |

| Hi Its a good plan although i can see a couple of problems. Plastic drainpipe has a thin wall thickness and will deform/crush under the weight of the broomsticks, especially the lower hubs which take the majority of the weight. It`d be better to use schedule 40 pressure pipe which has a much thicker wall. To provide a positive fixing the spikes should be threaded and angled to 16/18 degrees. An alternative to hubs for a small dome like this is to use screw-in eyelets instead of spikes and fix them together with a single bolt.Ideally they should be bent to the correct angle after fitting. The downside is the eyelet thickness will stack up so the struts will not be level where they meet at the vertex. Yet another option is to use steel or aluminium tubing for the strut ends and use the broomsticks for the struts. There more than one way to skin a cat :) | |

|

|

| posted by Out2lunch | 18/05/2008 00:46:29 |

|

Thanks for this Colin, I was thinking of the thicker stuff that you mentioned but wasn't sure of the name. Can someone tell me though where I measure from though for my calculations. Do I need to add some or all of the hub as part of the strut length? Ie according to my diagram above measure from A to A, or A to B, or even B to B? As this is important for the B strut length. |

|

|

|

| posted by colin | 18/05/2008 01:41:07 |

| A dome is always measured from the imagined spherical centrepoint of the dome to the outside of the vertices. The strut length will be from the exact centrepoint of one vertex to the next. A flat hub doesn`t come to a "point" so the point has to be calculated or imagined to exist :) The actual "point" location will depend on the axial angle on the strut end. For most purposes if you subtract one hub diameter from the calculated strut length it will be close enough. For example,a 6m diameter 2v dome requires struts of 1640mm and 1854mm (vertex to vertex) if your hubs are 75mm diameter subtract this from the calculated strut lengths to give 1565mm and 1779mm. In reality the calculated point of the vertex for a 75mm hub with a 2v design is 12.5mm outboard of the hub centre due to the 18 degree axial angle, subtracting 37.5mm from each end of the strut is slightly inaccurate as the actual distance from the edge of the 75mm hub to the vertex point along the 18 degree angle is 40mm :) | |

|

|

| posted by Out2lunch | 18/05/2008 11:00:53 |

|

You are a legend, thanks a lot for that, I got a bit lost with the maths at the end but I sort of understand where your coming from, so not to self subtract 1 hub diameter from the strut length to give you the correct strut length to make.

I will source the materials for this over the next week or so, and once I have created this festival monster I will take some photos and materials list so if anyone else wants to make one they know what to get. Thanks again for the help. |

|

|

|

| posted by colin | 18/05/2008 14:45:38 |

| Don`t forget you`ll need to match the hub diameter to the timber width you plan to use, a 75mm hub isn`t big enough for 44mm wide timber ;) The hub length will need to be slightly longer than the timber depth due to the angle. The pipe you need is called 160 psi pressure pipe, the wall thickness is ~6mm or more depending on the diameter. | |

|

|

Login to add resources

Copyright © 2013 Geo-Dome.co.uk. All Rights Reserved.