| Navigation |

| Geo-Dome Home |

| Forum Home |

| View All Threads |

| New thread |

| Member login |

| Title: | Sourcing Materials | |

| Posted on: | 4/21/2008 2:08:29 PM | |

| Category | Construction Techniques and Tips | |

| Author | Fearpig | |

| Status | Open | |

| Views | 8111 | |

| Replies | (13) | |

| Hello! I''m trying to price up components for a 3m (radius / height) 2V dome. I''m still undesided as to go with either plastic or steel for the frame and want to compare prices... Can anyone recommend a source for steel or plastic tubing for use in the frame? Thank you! | |

|

|

| [ Comments 13 ] |

| posted by colin | 21/04/2008 16:58:14 |

| Hi If you`re stateside, EMT conduit is your best bet as steel will be much stronger than plastic. You may need to adjust the design size to make the best use of the stock tube lengths, a 3m radius 2v will need 30 tubes at 74.5" and 35 tubes at 66". You`d be ok with 12ft tubes. | |

|

|

| posted by Edd | 26/05/2008 01:53:10 |

| I've seen domes with plastic hub connectors, I'm trying to get hold of some does anyone have a contatc for a company that manufactures them? | |

|

|

| posted by colin | 26/05/2008 13:42:07 |

| Hi Edd Can you describe these plastic hub connectors in a little more detail For instance were they a single tube, a plate or individual tubes that bolt together at the center. Were the struts on the dome made from pvc tube or timber? | |

|

|

| posted by edd | 29/05/2008 01:33:25 |

| Hi Colin, I saw them at a UK festival called glade festival. They were a series of tubes mounled together with a plate so that the entire hub was one piece. I really want to build a dome and have been looking at the conduit style design of flattening the ends and using bolts. Because it's my first time and the learning curve is half the fun I'd like to source some ready made hubs, from there I could buy the struts. Once I'd put together what would essentially be a kit I'd like to then go onto building a dome from scratch. The main sting that conerns me is the angles that are needed for the hub. I've seen plenty of ready made steel hubs for houses etc but these seem to be for large bits of timber. Is there any way of getting hold of ready made dome hubs for a 3v dome? | |

|

|

| posted by edd | 29/05/2008 01:34:42 |

| Edit *mounled* not sure how that happened it was meant to say moulded!! | |

|

|

| posted by edd | 29/05/2008 01:39:06 |

| I'm really impressed with the hubs these guys use. How hard (i'm a complete novice) would it be for me to build the same uhbs or ideally get hold of some? geodesicdesign.blogspot.com | |

|

|

| posted by Colin | 29/05/2008 04:30:05 |

| Hi Edd If i`m not mistaken thats Dave`s dome and he used at least some info from the site.The hubs are simply short lengths of pvc pipe, my old 3v used pretty much the same type of hub system ;) Making tubular hubs is quite easy providing you have the right tools. Building a few relatively simple wooden jigs is very worthwhile too as fabricating dome parts always involves repetitive cutting and drilling. | |

|

|

| posted by Colin | 29/05/2008 05:38:20 |

| If you give me an idea how big a dome you were planning to build for your initial test, along with the likely timber size (2x2,2x4 etc)i could give you a better idea of what you`d need. If you want some instant domebuilding fun you might be surprised to hear that there are literally hundreds of places in the uk where you can buy a 3v 5/8 geodesic dome frame kit with no drilling or cutting necessary :) The only downside is it isn`t really big enough to be useful at ~10ft dia x ~6ft high. | |

|

|

| posted by Colin | 29/05/2008 14:24:15 |

Here`s my old 3v for reference, anyone with reasonable DIY woodworking skills could build it.I used 75mm diameter (16 bar) pvc pressure pipe for the hubs, although it seems the price has gone up considerably since i last bought some. No doubt due to the ever increasing price of oil.

|

|

|

|

| posted by edd | 29/05/2008 22:29:08 |

| I've had a look at the hub angles in another thread on the site. In theory would I simply have to get the pipe and the drill the holes at those angles. It would be great to see some kind of drawing of a PVC tube hub if anyone has one. Or some instructions on how to drill the holes effectivley | |

|

|

| posted by Colin | 30/05/2008 03:55:01 |

Hi Edd

Thats all there is to it..sounds pretty easy doesn`t it :)

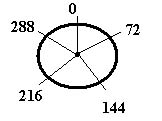

This is the plan view layout for the 5 way hub used at the center of the pentagons. The holes are drilled around the center line height of the hub. Apologies for the dodgy draftsmanship..i prefer a pencil and paper :)

To give you a scale of the task, the dome in the picture above required a total of 660 holes to be accurately drilled. If you are a master craftsman with plenty of time on your hands you could probably measure, mark and drill each one individually ;)

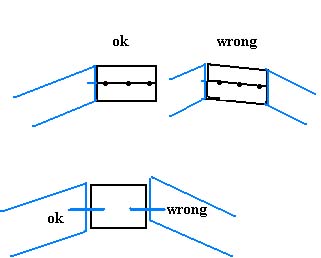

Mere mortals need to substitute some ingenuity for skill and use homemade wooden jigs to simplify the various tasks. There are a few important things to watch out for when fabricating dome components. Cutting the tubing off at exactly 90 degrees is very important. If the hub tubes are not cut off perfectly straight you will have an undulating guideline for the hole drilling process which will result in the struts meeting the hub like a wave..not good :)

If the holes in the strut ends are not drilled accurately the struts themselves will protrude above or below the hub..also not too good.

To give you a scale of the task, the dome in the picture above required a total of 660 holes to be accurately drilled. If you are a master craftsman with plenty of time on your hands you could probably measure, mark and drill each one individually ;)

Mere mortals need to substitute some ingenuity for skill and use homemade wooden jigs to simplify the various tasks. There are a few important things to watch out for when fabricating dome components. Cutting the tubing off at exactly 90 degrees is very important. If the hub tubes are not cut off perfectly straight you will have an undulating guideline for the hole drilling process which will result in the struts meeting the hub like a wave..not good :)

If the holes in the strut ends are not drilled accurately the struts themselves will protrude above or below the hub..also not too good.

The jigs must match the size of tube and the timber you plan to use for the dome but overall they are not difficult to make. The jigs will enable you to drill all 660 holes in perhaps just an hour or two, super accurately without any marking and measuring malarky.

The jigs must match the size of tube and the timber you plan to use for the dome but overall they are not difficult to make. The jigs will enable you to drill all 660 holes in perhaps just an hour or two, super accurately without any marking and measuring malarky.

|

|

|

|

| posted by Colin | 01/06/2008 09:01:43 |

|

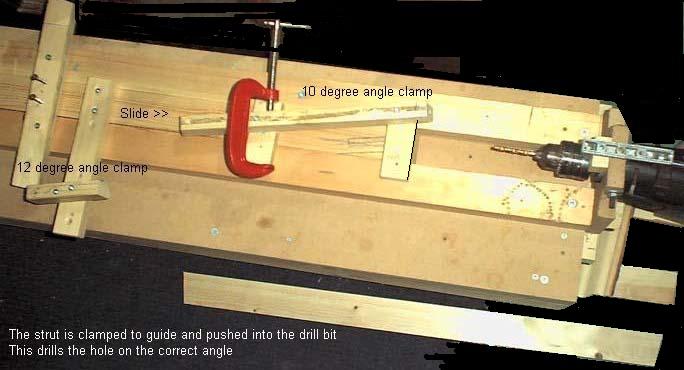

To give you some idea of how simple the jigs are here`s one :) A strut end drilling jig. |

|

|

|

| posted by Colin | 01/06/2008 09:34:10 |

Here`s another "tried and tested" way to do it.

Fix a drill rigidly in place ideally using a drill clamp and push the strut into the drill bit at the correct angle. It does the job well and is fairly rapid. It looks a little dodgy from a safety point of view but as the strut is clamped and pushed from the end..no body parts are within 2-3ft of the drill itself :)

Fix a drill rigidly in place ideally using a drill clamp and push the strut into the drill bit at the correct angle. It does the job well and is fairly rapid. It looks a little dodgy from a safety point of view but as the strut is clamped and pushed from the end..no body parts are within 2-3ft of the drill itself :)

|

|

|

|

Login to add resources

Copyright © 2013 Geo-Dome.co.uk. All Rights Reserved.