Tweet

| Navigation |

| Home |

| Site map |

| Articles |

| Contact |

| Links |

| Forum |

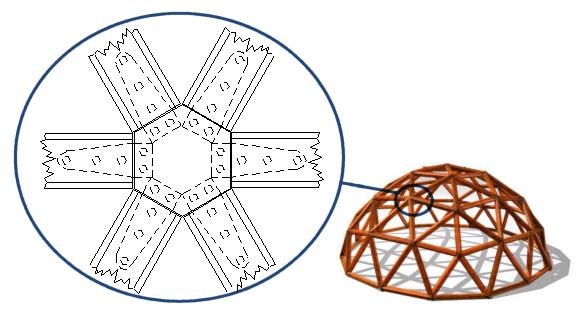

building a wooden geodesic dome greenhouse frame There are two types of block, hexagon (six sided) and pentagon (five sided) each block has a set of hinges fixed to the base that are used to attach and swing the beams into place. When the joints are assembled a large screw can be drilled into the top to fix the joint permanently.  Building a geodesic dome using this system should be relatively straightforward. Because the construction is all wood, adjustments can easily be made as the dome is being assembled. Fitting a covering is also pretty straightforward, rebates can easily be cut in the beams to accept glass or ply panels.  The only thing to be careful with is the blocks, they need to be very strong and not prone to splitting, as this would weaken the dome considerably. I would laminate the blocks making sure that each layer has the grain running at right angles to the one below. Next I’ll workout the angles for the beams and maybe build a prototype. If anyone can see a reason why this technique wouldn’t work or if I’ve missed something leave a comment below and let me know, I find the feedback most useful. |

|

|

|

| [ comments 62 ] |

| posted by Colin | 08/02/2007 18:35:32 |

|

|

| Hi Paul, Good to see you are planning another dome. For a 3v you will get away with perfect hexagon and pentagon hub blocks,the angles wont be too far adrift. The "120" hinges are (imho) an unnecessary expense. I don`t really see any reason for using a hinge as the angles are set by the strut end cuts (10 or 12 deg in the case of a 3v) Cheaper to use plain old steel strip. Your illustration shows 6 fixings per strut end, for a total 720 in the 3v 4/9 dome. That`s a lot of screws and perhaps more opportunities to split the wood. A cheaper/easy alternative may be to use simple 18mm thick plywood hub plates. Angle and notch the (2x4) strut ends to fit the plate at the correct angle. Drill and fix the strut to the hubplate with a single 10mm coach bolt (or even a well fitting hardwood dowel for a metal free structure) Less work, and gets you to the fun part of building the dome in less time :) | |

|

|

| posted by Johanna | 24/03/2007 17:53:25 |

|

|

| Hi, I work for the Centre for Contemporary Art and the Natural World and we are about to start a year-long programme called 'Wood Culture' - which will be looking at the beauty, usefulness and sustainability of using timber in construction. As part of the education side, I want to use a kit of parts for kids to learn how to make a geodesic dome - the joints always seem to be the problem if you want to scale down the size of the dome and use wood lengths. So how is it progressing? Is there a kit of parts which you could design for us?! | |

|

|

| posted by Colin | 25/03/2007 16:38:03 |

|

|

| Hi Johanna I love that "Beginner`s Way" footpath on your website :) It is very possible to make an all timber dome with no metal involved. The size and frequency is quite important, you`d need to be very accurate when cutting lengths and angles for a very small dome Larger domes are a lot more forgiving. Timber thickness and hub diameter will also dictate the minimum size, otherwise the hubs could look disproportionate to the dome itself :) 3v is generally the most common format, 3v 5/8 makes for a good looking geodesic. 3v 3/8 is fine too but not as tall and really needs a riser wall to "finish it off" cosmetically. The 2v design is less impressive in appearance and generally built for it`s economy of materials rather than it`s looks. Kids love geodesics and have even been known to abandon the gameboy to play in/on them :) | |

|

|

| posted by colin | 16/07/2007 19:42:24 |

|

|

| what are the angle cuts on the struts for a 2v dome.also the lengths of each strut.Please thanx | |

|

|

| posted by Colin | 18/07/2007 03:10:37 |

|

|

| Hi Colin The end angles are 16 degrees for the short struts and 18 degrees for the long ones. The actual lengths will depend on the radius of the dome you want to build. | |

|

|

| posted by ian | 29/07/2007 14:56:39 |

|

|

| I tried a prototype with the block and found cutting the block not easy. I ended up cutting two blocks and sticking them together to make the height. In the end I gave up due to the wood splitting (many many screws) and it is not easy to construct, the drilling has to spot on | |

|

|

| posted by Colin | 30/07/2007 14:06:07 |

|

|

| Hi Ian It`s all good experience ;) Blocks made from softwood will stand a good chance of splitting due to the grain and the amount of screws. You could laminate layers of plywood.. stronger but more work. Construct a simple jig for cutting the hub shapes to make the job easier. (Hint: There`s no reason the blocks can`t be circular instead of hex or pent) Don`t be too disappointed with your first attempt..most people don`t get further than the planning stages. Fire up the saw and have another go :) | |

|

|

| posted by Tony Kerr | 18/08/2007 22:06:24 |

|

|

| I built one last december, use a drill to make a hole before you place the screw, no splitting... I will be adding my geodome projects to this page | |

|

|

| posted by Justin Snyder | 19/12/2007 06:35:28 |

|

|

| Man what an awesome site full of information. I just purchased 12 acres in the country and was looking for alternative housing for my family when I stumbled across your sight. I am in the beggining stages of designing what I need/want in a Geodesic Dome home and have one question....I read 3v, 2v all over the site and see that that means frequency...but what is that exactly? Thanks | |

|

|

| posted by Colin | 22/12/2007 05:42:54 |

|

|

| Hi Justin You certainly have enough space. The frequency of a dome is simply the degree of subdivision to the basic triangular face. This page will explain it in graphics Dome homes are usually based on the 3v design. | |

|

|

| posted by deb | 16/03/2008 06:02:33 |

|

|

| what are the angles to cut on a 3v dome and 20ft radius. Need angles for the cuts for the ends of each strut. | |

|

|

| posted by Colin | 18/03/2008 11:09:31 |

|

|

| Hi Deb 10 degrees for the "A" struts (shortest ones) and 12 degrees for the rest. | |

|

|

| posted by Kieran | 29/03/2008 17:33:02 |

|

|

| I have made a couple of geodesic spheres using the above mentioned technique of morticing the ends of the struts at the correct angles to take a biscuit and then bolting right through. This was very successfull. I used 2" x 1" tanelised roofing batten, 12mm marine ply and 8mm bolts with washers for one. The other I have properly jointed with all the struts mitered perfectly and glued together. The results are good, the bolted one makes an attractive garden sculpture, the other is smaller and I used it as a background, providing reference to my inspriations backing up my design work in an exhibition. I made the mortices in many differnt ways before i came up with a successfull and easy way to produce them. I tried using a bandsaw, tablesaw and basic router jig. The most successfull way was to clamp all the struts togther, ends lined up and then making a jig to support the routers base I just ran along the length. Further ideas i am having... I think it would be a good idea to first chamfer the edges to create a flat plane on each triangle on which to attach any sheet material. What i cant work out is what the correct angles should be. I think it would be very useful if someone could supply all of the angles in question. Perhaps a diagram. Im sure they must of been published by Fuller. Some sort of injection moulded chinese made plastic hub that takes standard sizes of timber joist would be nice. The fact that the angles become closer together and less crucial as the frequency increases, as nothing else is getting simpler, is comforting. | |

|

|

| posted by Colin | 30/03/2008 20:49:57 |

|

|

| Hi Kieran As the frequency increases so does the number of components involved. If you don`t work to very close tolerances they will add up to a very large cumulative error. | |

|

|

| posted by Andy | 11/01/2009 00:21:11 |

|

|

| Dear Colin, firstly i want to say thankyou. This is a brilliant site and since discovering it i have made 2 domes and seriously read up on bucky and his domes. My first dome was made of bamboo and is 2v with a diameter of 2.6 metres. the hubs were pvc pipe and wall plugs were used to hold the screws into the bamboo kind of inside out of the hub. From this experience i have learnt, bamboo makes for lots of construction nightmares. It is not uniform down its cross section and you can not nail or screw a canvas over it which means purchasing lots of polytunnel fixing tape. So hidden costs i had not forseen. recently i took this good example as my second dome and made it from treated timber, wooden hubs and zinc mending plates. If you shop about on the net these are very reasonable. 9p a throw. i bought a precision hand mitre saw for 15 quid from b and q and two very handy rachet clamps (essential like having 2 helpers). Also in my gardening plans im turning old pallet wood into isometric raised beds. This is in an effort to allow maximum spacial use for the planting. Another thing that has helped me immensely is a program called geogebra this i used to plan and also create paper jigs for all my constructions. even the pvc sheeting to ecomomise via tesselation. Anyway it has been a big nevertheless fun journey and someday i aim to have a dome on a mountain top. There are some photos of the work if you would ever like to see them. | |

|

|

| posted by Emu | 09/02/2009 23:37:25 |

|

|

| Hi all, I´m planning a 2V wooden sphere being hung between some trees and struggling with the angle of the panneling as I want to prebuild triangles instead of using struts and blocks. I found the angles for 3V here on this great site but not for 2V. Can anyone help?? | |

|

|

| posted by simon | 10/02/2009 22:29:33 |

|

|

|

Hi Emu Bevel all the B-edges of the Y panels at 79 degrees. For the X panels it is the A-edges that you bevel at 79 degrees, and the B-edge at 83 degrees. Simon |

|

|

|

| posted by Joe | 14/03/2009 02:19:35 |

|

|

| Hi everyone. Just came across this site. Glad to see that there are many other geo freaks out there. I have tinkered with these domes for years but now my goal is to build a 4v, 30 foot radius monster green house. Lofty, I know. I haven't seen many 4v's and I want to be unique. Not to mention that the 4v dome has a naturally flat foundation like the 2v dome has. I am a math teacher by trade and have calculated all of the strut lengths and every possible angle for each one. This includes the dihedral angles which are the chamfered angles that Kieran was talking about. I have decided not to use any connectors at all, just glueing and screwing the compound miter joints together. I have no doubt that this will be strong enough but would like to run some tests to experiment. I hadn't considered biscuits until I read Kieran's submission. Thanks. The math really wasn't that difficult, just time consuming. I simply started out assuming I had an icosahedron placed inside a sphere of radius 1. Then I just used vectors to find everything. Going from a dome of radius 1 to a dome of radius 30 is simply a matter of multiplying the strut lengths by 30. All the different angles in a small dome are the same as the angles in a big dome. Incidentally Kieran, the angles you seek are all about 9 degrees in a 2v dome. | |

|

|

| posted by Joe | 14/03/2009 03:47:03 |

|

|

| Oops. Just realized that I only gave one angle. The 9 degrees is for all of the longer struts in the center of the original triangle. The struts that tie into the pentagons, the shorter ones, must have about 11 degrees shaved off. I'm sure 10 would work for both, don't know how precise you want to be. | |

|

|

| posted by simon | 14/03/2009 15:30:56 |

|

|

|

Hi Joe Remember that the long 2v strut has different size triangles on either side of it - if you want to cut a simple 72 degree mitre on its ends then you'll want to bevel one side by 11 degrees and the other side by 7 degrees - remember that the hub's position vector is in the strut's mid-plane. Simon |

|

|

|

| posted by Joe | 16/03/2009 06:07:49 |

|

|

| Hi Simon, You're absolutely correct in that the different size triangles create different angles. I simply divided the supplement of the dihedral angles by two to get my results. This will works for the shorter struts since the triangles on each side are the same size. However, it was incorrect to divide the angle by two with the longer struts. Thank you for pointing this out. When I went back to the calculator, my results were slightly different than yours. My numbers were 9.8 degrees on the equilateral triangle side of the long strut and 8.2 degrees on the pentagon side. Again, I do appreciate you pointing this error out. | |

|

|

| posted by simon | 16/03/2009 23:11:55 |

|

|

|

Hi Joe. What do you make the strut lengths for a 2v of unit diameter - 0.273 & 0.309? Simon |

|

|

|

| posted by Joe | 18/03/2009 01:06:38 |

|

|

| Hi Simon, Yes, thats what I get. Initially I used the numbers for a unit radius but recalculated them for a unit diameter just to double check myself. I got the same angles using the new numbers. When I calculate stuff like this I don't round anything until the final answer. Rounding a number and then using it in a subsequent calculation can cause rounding errors. For example, I didn't use 0.273 and 0.309 but rather 0.2732665289 and 0.3090169944. The easiest thing to do is to store all of your decimals in the calculator (many have multiple storage locations) and then recall them when you need them again. I did make another error though, I mixed up the sides of the strut in my last submission. It is the equilateral triangle side that is 8.2 degrees and the pentagon side that is 9.8 degrees. More precisely, my numbers are 8.236105 degrees, 9.792997 degrees and the angle between the faces is 161.970898 degrees. I was thrilled to find that these actually do add to be exactly 180 degrees. Joe | |

|

|

| posted by Joe | 18/03/2009 04:30:26 |

|

|

| Actually Simon, the more I think about it, I may be assuming something that is not true. Let me think about this some more and see if I can get your results. Joe | |

|

|

| posted by Simon | 18/03/2009 21:25:19 |

|

|

|

Hi Joe

We agree on the value of the dihedral angle but I think we're orienting the strut differently. I believe our approach is the same so let me know where we disagree: There is only one orientation of the strut that allows the ends to be cut with a simple bevel, and that's when the hub axes are in the strut's mid-plane. Consider a facet defined by three vertices a, b, c with position vectors a, b, c, such that the facets' struts have displacement vectors A, B, C where A = c-b, B = a-c and C = b-a.

BxC is an outward-facing normal to the facet, and bxc is normal to the equitorial plane that contains strut A, and the strut is oriented with its mid-plane alligned with that equitorial plane. The bevel angle on the left hand side of strut A is therefore 90 - alpha. For example, a pent facet from a 2v dome of unit diameter with rim strut A and spoke struts B and C can be described as: a = [0, 0, .5] b = [-.213, .155, .425] c = [-.213, -.154, .425] which gives the bevel angle on the A strut as 7.22 degrees, and as a check the struts lengths are A=.309, B=.273, and C=.274. Note that the bevel gets bigger as the other two struts get longer, so the hex (equilateral) side of the long strut has a bigger bevel than the pent side. Simon |

|

|

|

| posted by Joe | 19/03/2009 04:50:44 |

|

|

| Hi Simon. Nice solution. Your explanation was very good. We seek the same angle but a different location. In your drawing angle OAa is also equal to alpha which is the angle I was trying to find. Let point d be the midpoint of vector A. Since triangle abc is isosceles, angle adb is a right angle. Using the same formula that you used, I found alpha with vectors d and d-a. When I use your vectors a, b, and c I too get a bevel angle of 7.22 degrees. My only guess is that I have an incorrect value somewhere because the calculations are the same. Using cross products would be handy for larger frequencies that don't have isosceles triangles to exploit. Thank you for taking the time to draw a figure that is easy to understand and for your explanation. Joe | |

|

|

| posted by simon | 20/03/2009 00:07:44 |

|

|

| Hi Joe, thanks, I've enjoyed the exercise. | |

|

|

| posted by Soren | 21/03/2009 14:14:10 |

|

|

| I am building an 18 foot 3v 5/8 dome greenhouse. This is my first one other than a plastic straw model. I am using reclaimed 2x3's from a renovated basement. Again this been my first real dome I was wondering what angles I should cut the end of each strut. Strut lengths are: A - 3.137 B - 3.631 C - 3.711 I have all the materials I need. Just need to find the angles and I am ready to roll. Thanks Soren | |

|

|

| posted by daveindeal | 28/03/2009 17:31:10 |

|

|

| at the bottom of the 3v calcualtion tool (scroll all the way down) it shows you the strut angles to cut the ends. | |

|

|

| posted by Alex | 11/05/2009 23:31:54 |

|

|

| Hi, I'm building a 3v 5/8 dome which I want to cover with the metal cut from scrap car tops similar to the first Drop City domes in Colorado. I'm starting with a 4.5 test dome. I don't love the hub solution, but to bolt triangles together seems wasteful of material. Is it possible to build from 2x4 and fix without hubs? Thanks Alex | |

|

|

| posted by simon | 14/05/2009 17:16:20 |

|

|

|

Hi Alex You have to think about how the forces are being distributed and transmitted. If you're talking about a dome made from sheet-metal triangles joined together at batterns then at one extreme you have a stressed-skin dome where the panels distribute all the forces and the batterns none, to the other extreme where the batterns distribute all the forces through their hubs and the skin contributes nothing. Structural engineering isn't my thing so I hope you get some better answers than I can offer, but my suggestion is: no, if your 4x2s are structural then they need substantial hubs to distribute their forces, and if they're not structural then you hardly need them at all. Where are you seeing wasted material? |

|

|

|

| posted by Ed in Central Victoria Au | 12/07/2009 13:16:55 |

|

|

| Hey all I'm building a 3.6m diameter 2v with 2m riser walls. The construction will be from 90x45 ply planks, the hubs being 3 planks laminated and cut on a table saw. Covering will be 30mm of ferrocement and a coating of elastomeric paint. Should be no seasonal movement, I figure. I've made doors with very close tolerences from this ply, and they don't move like the hardwood doors I've made. Anyone see any problems with this design? Cheers Ed | |

|

|

| posted by davy | 06/11/2009 18:17:01 |

|

|

| I am wanting to build a Panelised 2v dome with out Plywood, I am haveing a hard time figureing out what to bevel each sides of the panel, can i get some help? | |

|

|

| posted by sagaro | 16/01/2010 19:39:10 |

|

|

| Joe, if u ever read this again.. i am looking at making a 6v, but need those hub angles, dihedral angles.. i am not using hubs, but instead putting my struts together to a point... could use some help, improvedadam@hotmail.com | |

|

|

| posted by Mike | 24/01/2010 20:40:54 |

|

|

| One big problem! In the formula for calculating no data blocks and their sizes. Dimensions beams frame will be mistaken. Correct the formula in the light of the blocks. Specify the size of five and six hedron | |

|

|

| posted by paul | 30/01/2010 15:37:48 |

|

|

| To prevent the blocks splitting use elm [Ulmus spp]it is almost impossible to split hence its use as wooden wheel hubbs. | |

|

|

| posted by mark | 22/05/2010 23:04:55 |

|

|

| im in the midst of building a 3V dome and I'm confused as to what angles to cut the beams. in the calculation tool, it says to cut 'A' at 80 degrees, 'B' at 78.3 degrees, and 'C' at 78 degrees. However, I'm also reading that the 'A' strut only needs to be cut at 10 degrees at the end and the rest at 12 degrees. Can someone offer some insight? Perhaps I'm just missing one piece of info but I would like to clear this up as soon as possible. Thanks | |

|

|

| posted by mark | 23/05/2010 00:18:16 |

|

|

| i'm wondering at what angle to cut the end of the beams because in the calculation tool it says for 'A' to be cut at 80 degrees, 'B' at 78.3 degrees, and 'C' at 78 degrees. BUT then I'm reading elsewhere on the site to cut the 'A' beam at degrees and the rest at 12 degrees. Any insight? | |

|

|

| posted by Admin | 23/05/2010 11:04:16 |

|

|

| Hi Mark, first off you don't need to worry about decimal places as your saw won't be able to cut to 0.3 of a degree. OK on an 'A' strut you set the saw to 10 degrees and cut the end, this leaves 80 degrees on the end of the wood. | |

|

|

| posted by William | 04/06/2010 00:32:27 |

|

|

| I am planning a 6 foot radius 3v stressed skin dome. I have everything figured out except the foundation angles. I am planning on riser walls but have not found anything that helps. Any advice or links would be appreciated. | |

|

|

| posted by Leon Penney | 10/01/2011 21:16:02 |

|

|

| I am looking for the hub axis angles for the the struts on a 4V dome. | |

|

|

| posted by Doris Witherspoon | 04/04/2011 06:18:56 |

|

|

| Will someone take a look at my Geodesic Domes at www.goodkarmadomes.com click on Lila palace. I need to paint them because I have a few leaks. What type of paint should I use. The domes are located in Angie, La. I need a painter/roofer in my area please advice | |

|

|

| posted by David Jenkins | 22/04/2011 18:37:40 |

|

|

| Do the length of the struts have to take into account the width of the hub? | |

|

|

| posted by Tessy | 28/04/2011 15:06:54 |

|

|

| I am building a small geodome that I plan on tipping to its side and putting on a base. I am going to use it for outdoor seating. Any advise. | |

|

|

| posted by Kris | 15/05/2011 02:07:05 |

|

|

| Building a 3v 5/8 dome and I need to know if the struts are beveled on the edges. If so, at what degrees for A,B! And C. I am not speaking of the end cuts here but instead the length of the struts. Please advise. Thank you! I am not using hubs only triangled wood struts. | |

|

|

| posted by Neodim Kollobok | 27/11/2011 20:37:13 |

|

|

| All the calculations for many types of geodomes are online: simplydifferently.org/Geodesic_Dome_Notes | |

|

|

| posted by Sara | 10/01/2012 01:25:55 |

|

|

| i have seen in several online blogs about geodesic domes with varying degrees when regarding the angles of the hubs. Are all the hexagon hubs regular (60 degrees) and all the pentagons regular (72 degrees)? | |

|

|

| posted by Josh | 28/02/2012 02:05:43 |

|

|

| To Colin, first comment. I am interested in this 18 mm plywood hub cap strategy, but it is not making any sense to me at all. Does this cap go on top of the hub and overlap all the studs to connect them, or is it like a buffer zone between the stud and hub which have to be notched. Not sure how a coach bolt can be secured. | |

|

|

| posted by racingangle | 26/03/2012 00:17:22 |

|

|

| I am trying to build a 20ft Bio-dome can you tell me how long my 2x4's have to be and will all struts be the same length? The struts are 10 and all others 12 degrees can u tell me if that's right? | |

|

|

| posted by michael | 10/05/2012 20:34:23 |

|

|

| im looking to start a dome. im thinkin 30ft diam 2v on 9 foot walls. im unsure of the angles and bevels at strut connections. any help? or examples of connection points would be helpful also. | |

|

|

| posted by Bill | 15/06/2012 06:14:01 |

|

|

| Hello, Im a carpenter with tons of framing experience and quite confident int the bevel and angle cuts of the 3v dome. I am confident with the strut calcs, bevel and angle cuts I can follow and accurately cut them all. My question is what is the bevel angle down the length of the strut for a 3v dome in order to attach the outside panel to the center of each strut. When I framed homes I would often bevel my hips and vallys so there was no gap under the point of the hip if the member was wide. I can't seem to find the bevel angle for this does anyone know or is it so insignificant it's not worth it? | |

|

|

| posted by Gerald | 07/09/2012 07:17:09 |

|

|

| I am thinking of building a 2v dome , using 2x4 timber struts. The diameter is 4880 mm . I have used the calculator on this site and the length of strut B is showing 1508.03 mm . Am I right in assuming that this is the overall length of strut after angles are cut and compound miters removed . I would like to join all struts without using hubs, hence the compound miters. regards Ger. | |

|

|

| posted by ipsd48 | 14/12/2012 21:40:51 |

|

|

| Could always try pre-drilling the holes for the screws. Use a bit of bar soap on the threads so they'll lock in place | |

|

|

comments will be accessed through the forum in the new site design (coming soon)

22194

Copyright © 2007- 2014 geo-dome.co.uk. All Rights Reserved.