| Navigation |

| Geo-Dome Home |

| Forum Home |

| View All Threads |

| New thread |

| Member login |

| Title: | Low cost geodesic dome greenhouse kit questions | |

| Posted on: | 11/7/2008 2:42:03 PM | |

| Category | Construction Techniques and Tips | |

| Author | KeithT | |

| Status | Open | |

| Views | 50798 | |

| Replies | (9) | |

| Hi, Thanks for these plans, this is a great cost effective way to make a dome. We are using this technique to build a 10m dome. (Some pics attached re how far we have got. It seems doing this attracts rain cos it has been raining for 8-9 days solid and we are in the South of France !). Anyway, I have a couple of questions, if the plans author has a minute: 1. We put a hexagon and a pentagon together temporarily (the wood is soaked so we are waiting for it to dry out before final assembly) to make sure we had the angles correct and it all fitted together ok, before cutting the rest of the wood. The pentagon is reasonably stable as a unit, but the hex flexs quite a bit. Did you find this and does it stabilise when the dome is completed ? 2. We want to use this dome as a greenhouse for growing exotic stuff. We get lots of Sun but are at 300m altitude so still get frosts, which means winter night temperatures are an issue. We intend to put a pond and raised beds with stone walls to give us lots of thermal mass inside, but am now wondering about the tunnel plastic as a covering. I am guessing that the dome in the plans gets cold at night because of the relatively poor insulation from the tunnel plastic ? 3. I am investivating using ETFE cushions (like the eden project) which are becoming more and more mainstream and am in contact with some manufacturers, although nothing solid yet. Triangular cushions don''t seem to be that much more complex than tunnel sheeting (pump aside) and I wondered if you guys had any experience with them or contacts to recommend. Thanks in advance and a great site. Keith | |

|

|

| [ Comments 9 ] |

| posted by KeithT | 07/11/2008 14:45:34 |

|

|

|

|

| posted by admin | 07/11/2008 20:58:39 |

|

Nice job KeithT, To answer your questions: 1. Yes the hex panels are a little more flexible than a pent, don't worry it will all lock solid when you finish the dome. 2.Yes my dome does get cold at might, it also gets a lot of condensation. I thought putting another layer of poly film on the inside or even bubble wrap would help enormously. 3.I tried a small piece of ETFE and it was really cool, much tougher than poly film and it takes staples really well, it is a little harder to tension compared to poly and it won't heat shrink. It's still a bit on the dear side for me to use on a dome but when it gets more mainstream I'll definitely be using it. Have you got a door for the dome. Should look amazing when it's finished. I would love to see pictures |

|

|

|

| posted by Colin | 08/11/2008 01:55:19 |

| Hi Keith Thats a nice big dome,as Paul said don`t worry it`ll become very rigid when the last panel is fitted :) The issue with ETFE apart from cost is the width. It can be welded to create greater widths but the weld limits the thickness as it tends to be brittle. The Eden Project came up against this issue too :)The big plus of ETFE is its ability to withstand high temperatures, when normal poly gets hot it gets weaker, at a temperature of 80°C the yield strength of 2mil (50um) ETFE film can be compared with an 8 to 10mil (200-250um) horticultural poly. I`ve tested triangular pillows but didn`t find them too appealing. You`ll learn a lot about physics, mechanics and fluid dynamics if you go on the pillow dome route..i did ;) | |

|

|

| posted by colin | 09/11/2008 17:07:52 |

Keith

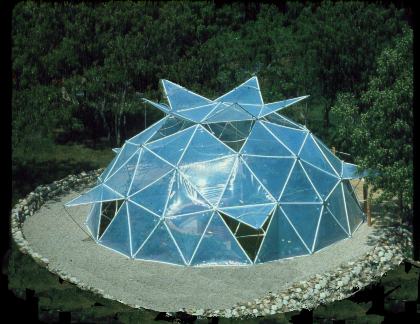

Here`s a pic of J.Baldwins pillow dome which i believe was the first to use inflated etfe pillows. He used argon gas not air ;)The dome was a 30ft so about the same size as yours.

|

|

|

|

| posted by KeithT | 10/11/2008 19:57:28 |

| Thanks for the answers guys. Colin I would be interested in finding out the unappealing aspects of the ETFE pillow approach ? Did you discover another approach to the transparency and thermal insulation issue ? Cheers Keith | |

|

|

| posted by colin | 10/11/2008 22:37:05 |

| Hi Keith A quick correction regarding J.Baldwins pillow dome pictured above,it was 50ft in diameter not 30ft as i first thought. After he tested the thermal performance, Baldwin recommended using conventional insulation in conjunction with the inflated pillows as on their own they were not the complete solution. It looks likely that the design also suffered greatly from thermal bridging of the aluminium frame to the cold outside world :) A double skin polytunnel cover is very simple compared to fitting inflated pillows on a dome. | |

|

|

| posted by Christopher Freitas | 01/12/2008 04:43:26 |

| I worked on J. Baldwin's pillow dome back in the 1980s and it was in the 30 foot range - not 50 foot in diameter. I agree that the design was affected by the thermal bridging of the structure - but that could have been eliminated with a better dome structure design. The biggest issue I remember was the radiate losses at night were high - so some type of reflective blanket might be required. | |

|

|

| posted by popitch | 12/04/2011 10:17:56 |

| This dome form in calculator =) acidome.ru/lab/calc/#5/12_Cone_3V_R4.8_beams90x36 | |

|

|

| posted by Greg | 09/02/2013 07:27:02 |

| Where can I get plans and tips? | |

|

|

Login to add resources

Copyright © 2013 Geo-Dome.co.uk. All Rights Reserved.